The Anatomy of Leather

From ancient civilizations to modern times, leather has played a significant role in our daily lives, gracing everything from fashion and furniture to tools and art.

Its versatility makes it a favorite across various industries, and it is appreciated not just for its practical uses but also for its aesthetic appeal.

But what exactly makes up this wonderful material? Let’s nerd out on the anatomy of leather.

The basics of leather

Leather, in essence, is a material created from the hides and skins of animals, most commonly cows. Its origins trace back thousands of years, with ancient civilizations using it for clothing, shelter, and tools.

Tanning is the process of turning raw animal hide into usable leather, and it has evolved significantly over time.

The leather journey begins with tanning, which involves treating the hide to prevent decay and make it more durable. Traditional tanning uses natural tannins from tree bark, while modern techniques often employ chromium salts for faster results.

After tanning, the hide is cured and dried, stabilizing it further and preparing it for the final steps.

Finishing is the last stage, where the leather is treated to achieve the desired texture, color, and feel. This can include processes like dyeing, buffing, and embossing. Each step in the leather-making process enhances its qualities, transforming it from a raw hide into a functional and beautiful material.

The structure of leather

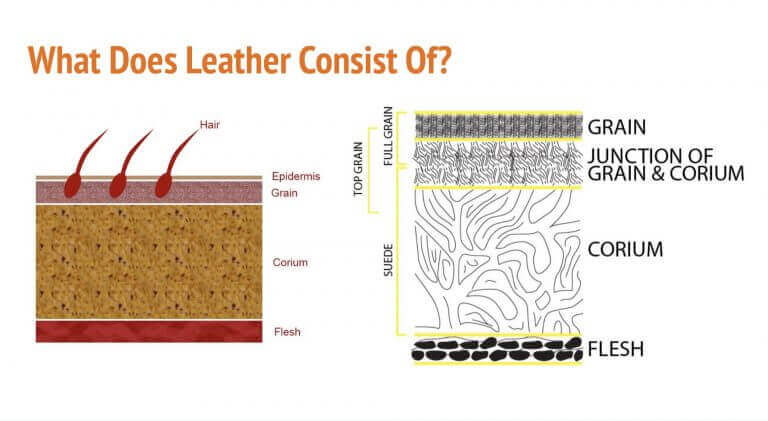

Understanding the structure of leather begins with the anatomy of the animal skin from which it is derived. Leather is primarily composed of three layers: the epidermis, dermis, and hypodermis. Each layer plays a crucial role in determining the final characteristics of the leather.

Epidermis

The outermost layer of the skin, the epidermis, is thin and serves as a protective barrier for the underlying tissues. In leather production, the epidermis is usually removed during the tanning process, as it does not contribute significantly to the strength and durability of the finished leather.

Dermis

The dermis is the most important layer for leather production. Located beneath the epidermis, it is composed of densely packed collagen fibers, which are responsible for leather’s strength, flexibility, and resilience. The arrangement and density of these collagen fibers vary across different parts of the hide, influencing the quality and characteristics of the final product.

The dermis itself can be further divided into two layers: the papillary dermis and the reticular dermis. The papillary dermis is closer to the surface and contains finer collagen fibers, while the reticular dermis, located deeper, has thicker and more robust fibers. The quality of leather largely depends on the thickness and condition of the reticular dermis.

Hypodermis

The hypodermis, also known as the subcutaneous layer, lies beneath the dermis and primarily comprises fat and connective tissue. This layer is generally removed during the initial stages of leather processing, as it does not contribute to the leather’s desirable properties.

The key to leather’s durability and versatility lies in the collagen fibers within the dermis. These fibers are arranged in a crisscross pattern, giving the leather its unique combination of strength and flexibility. The tanning process further enhances these properties by stabilizing the collagen structure, making it resistant to decomposition and wear.

Understanding the structure of leather helps us appreciate the complexity and craftsmanship involved in its production. It also provides insight into why different types of leather have distinct characteristics, depending on which part of the hide they are sourced from and how they are processed.

Leather comes in various types, each with unique characteristics, quality, and uses. The type of leather is determined by factors such as the part of the hide used, the tanning process, and the finishing techniques applied. Here, we explore the most common types of leather and what makes each one special.

To get more scientific…

Let’s get a bit more scientific, shall we?

To fully appreciate leather’s unique properties, one must delve into its intricate scientific structure, particularly focusing on bovine leather. This section explores the complex anatomy of leather, emphasizing key elements such as collagen fibrils, fibre bundles, and the grain surface.

The building blocks: Collagen fibrils and fibre bundles

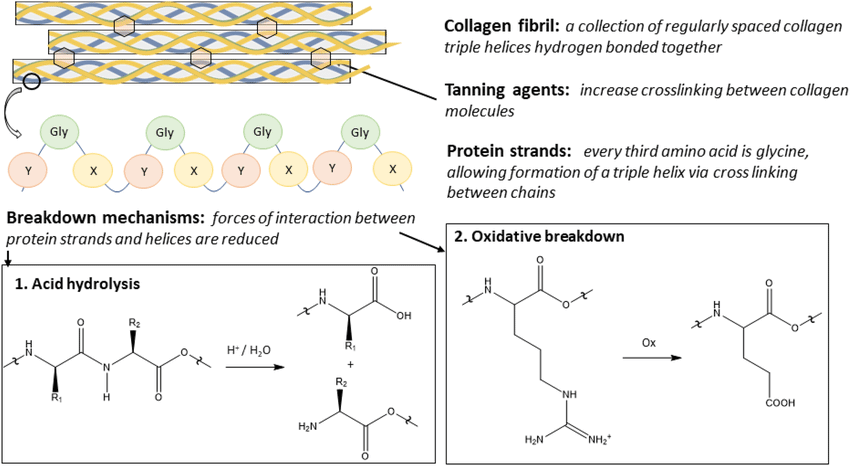

At the heart of leather’s structure are collagen fibrils, which are the fundamental fibrous proteins that provide leather with its renowned high tensile strength and durability. Collagen fibrils group together to form fibre bundles, contributing to the material’s overall robustness.

These fibrils are interwoven hierarchically, creating a flexible and resilient network essential for the high tensile strength observed in quality leather products.

Layers of leather: From the outer surface to the corium

Leather is composed of several layers, each contributing to its unique properties:

- Outer Surface (Grain Surface):

- The outermost layer, known as the grain surface, is characterized by a smooth, dense texture that offers aesthetic appeal and durability. It houses follicles, which are small openings where hair once grew, contributing to the distinctive texture of the leather.

- Papillary Layer:

- Beneath the grain surface lies the papillary layer, a thin section rich in fine collagen fibrils. This layer provides additional strength and flexibility, crucial to the material’s ability to withstand stress without tearing.

- Corium:

- The corium is the thickest layer, situated below the papillary layer. It consists of densely packed fibre bundles and collagen fibrils, offering the bulk of leather’s structural integrity. The corium’s composition allows for significant tensile strength and durability, making it a vital constituent in the overall strength of leather.

The role of tannage in leather stabilization

Tannage, the process of treating raw materials to convert them into durable leather, plays a critical role in stabilizing the structure of leather. Through this process, the collagen fibrils and fibre bundles undergo chemical transformations, enhancing their stability and decomposition resistance.

Various tannage methods, such as vegetable tanning and chrome tanning, introduce different chemical agents that interact with the collagen fibrils, leading to the desired properties in the finished leather.

The influence of materials science on leather quality

Materials science plays a pivotal role in understanding and improving leather quality. Studies by experts like Haines and Barlow have shed light on the microscopic interactions within leather, such as the alignment and bonding of collagen fibrils and the effects of different tannage techniques.

By examining these interactions, scientists can develop innovative methods to enhance leather’s durability, flexibility, and overall performance.

The anatomy of leather is a testament to the complexity and ingenuity of natural materials.

Schematic showing a simplified structure of leather.

By understanding the scientific underpinnings, from the microscopic collagen fibrils to the macroscopic structure of the corium, one can appreciate the remarkable properties that make leather a material of choice across various industries.

Continued research in materials science and advancements in tannage techniques promise to elevate the quality and versatility of leather further, ensuring its relevance in the modern world.

Leather finishes and treatments

The finishes and treatments applied during the manufacturing process significantly influence leather’s final appearance, texture, and durability.

These treatments can enhance the leather’s natural qualities or give it a completely different look and feel. Here are some of the most common leather finishes and treatments.

Aniline and semi-aniline finishes

Aniline leather is treated with soluble dyes that penetrate the leather, providing color without altering the natural surface.

This type of finish retains the hide’s natural texture, including any imperfections or markings, giving it a unique and authentic look. Aniline leather is soft and supple but can be more susceptible to stains and fading due to the lack of a protective coating.

On the other hand, semi-aniline leather undergoes a similar dyeing process but also receives a light surface coating. This coating protects against wear and stains while preserving much of the leather’s natural character.

Semi-aniline leather balances the natural look of aniline leather and the durability of protected leather.

Pigmented and protected finishes

Pigmented leather is treated with a layer of pigment on its surface, which provides a uniform color and a more robust protective layer. This finish covers most of the hide’s natural imperfections and grain, resulting in a consistent appearance.

Pigmented leather is highly durable and resistant to scratches, stains, and fading, making it ideal for high-traffic applications like furniture and car interiors.

Protected leather refers to any leather that has received additional treatments to enhance its durability and resistance to damage. This can include protective coatings, waterproofing, and other treatments that extend the leather’s lifespan and maintain its appearance under various conditions.

Nubuck and suede

Nubuck leather is created by sanding or buffing the outer layer of the hide to produce a soft, velvety surface. It is similar to suede but is made from the top grain of the hide, making it more durable.

Nubuck leather has a luxurious feel and is often used in high-end footwear and accessories. However, it is more prone to staining and requires careful maintenance.

As mentioned earlier, suede is made from the inner layers of hide and has a napped finish. It is softer but less durable than nubuck. Suede is popular for its distinctive texture and appearance and is frequently used in fashion items like jackets, shoes, and handbags.

Like nubuck, suede requires special care to maintain its look and feel.

Embossed and Printed Leather

Embossed leather is stamped with patterns or textures to give it a decorative appearance. This process can mimic exotic skins like alligator or crocodile or create intricate designs. Embossed leather allows various creative applications in fashion, accessories, and interior design.

Printed leather involves applying patterns or images onto the leather surface using various techniques, including screen printing and digital printing. This treatment can produce vibrant and detailed designs, adding a unique aesthetic to leather goods.

Impact of finishes on durability and aesthetics

The choice of finish and treatment not only affects the leather’s appearance but also its performance. Aniline and semi-aniline finishes offer a natural look but require more maintenance.

Pigmented and protected finishes provide greater durability and ease of care, making them suitable for everyday use. Nubuck and suede offer luxurious textures but need careful handling to avoid damage.

By understanding the different finishes and treatments, consumers can select leather products that best meet their needs and preferences, whether prioritizing aesthetics, durability, or ease of maintenance.

Applications of leather

Leather’s versatility and durability make it a popular choice across various industries. Its unique characteristics lend themselves to various applications, each taking advantage of the material’s strengths and aesthetic appeal.

Fashion and Accessories

Fashionable leather accessories.

Leather has long been a staple in the fashion industry, celebrated for its timeless style and durability. High-quality leather is used to craft an array of fashion items, including:

- Shoes: From elegant dress shoes to rugged boots, leather footwear is prized for its comfort, durability, and classic look.

- Bags: Leather handbags, briefcases, and backpacks offer a blend of style and functionality and often become more attractive with age.

- Jackets: Leather jackets are iconic fashion pieces. They provide warmth and protection while adding a stylish edge to any outfit.

- Belts and Wallets: Leather is a strong material that develops a rich patina over time, making it ideal for everyday accessories like belts and wallets.

Furniture and Interior Design

Leather is popular in furniture and interior design due to its luxurious feel and durability. Common applications include:

- Sofas and Chairs: Leather upholstery is valued for its comfort, longevity, and ease of cleaning. It adds a sophisticated touch to living spaces and offices.

- Car Interiors: Leather car seats and interiors are a hallmark of luxury vehicles, offering comfort, elegance, and durability.

- Home Decor: Leather is also used in home decor items such as cushions, throws, and wall panels, adding texture and warmth to interior spaces.

Industrial and Specialty Uses

Beyond fashion and furniture, leather finds applications in various industrial and specialty contexts:

- Tool Grips and Protective Gear: Leather’s durability and grip make it ideal for tool handles, gloves, and protective gear used in industries like construction and welding.

- Sports Equipment: Leather is used to produce sports equipment such as baseball gloves, footballs, and equestrian gear. It is valued for its toughness and ability to conform to users’ needs.

- Musical Instruments: Drumheads, accordion bellows, and bagpipes often feature leather components for their durability and responsiveness.

Emerging Trends and Sustainable Practices

The leather industry is evolving with a growing focus on sustainability and ethical practices. Innovations include:

- Eco-Friendly Tanning: Processes that reduce environmental impact by using natural tannins and reducing water and chemical use.

- Recycled Leather: Utilizing leather scraps and waste materials to create new products, minimizing waste and promoting sustainability.

- Alternative Leathers: We are developing leather alternatives from plant-based materials and lab-grown leather, offering similar qualities without the environmental and ethical concerns associated with traditional leather.

Leather continues to be a versatile and valued material, finding new applications and adapting to modern needs and sensibilities. Its enduring appeal lies in its unique combination of beauty, strength, and adaptability.

Fibrenew: The mad scientists behind masterful leather restoration

Get in touch with your local Fibrenew professional for all your leather, plastic, and vinyl repair needs.

Want to run a business that gives you incredible earning potential and the flexibility to take control of your time and life? Join the Fibrenew Family!

Check out our free Franchise Information Report for everything you need to know.

Also, enjoy these valuable resources on all things leather, plastic, and vinyl repair, franchising, sustainability, and more:

Stay tuned!

What is leather made from? Leather is made from animal hides and skins, most commonly from cows. Other animals like goats, sheep, and pigs are also used, but cowhide is the most prevalent due to its availability and quality. What are the main layers of leather? Leather primarily consists of three layers: the epidermis (outer layer), the dermis (middle layer), and the hypodermis (inner layer). The dermis is the most important layer for leather production, as it contains the collagen fibers that provide strength and durability. What is full-grain leather? Full-grain leather is the highest quality leather, made from the hide’s top layer. It retains the hide’s natural grain, including imperfections, and develops a patina over time. It’s prized for its durability and natural appearance. How does top-grain leather differ from full-grain leather? Top-grain leather also comes from the hide’s top layer but is sanded and refinished to remove imperfections. It offers a more uniform appearance than full-grain leather but doesn’t develop a patina similarly. It is slightly less durable but still of high quality. What is genuine leather? Genuine leather is a lower-quality leather made from the layers of the hide left after the top layer is split off. It is more affordable and less durable than full-grain or top-grain leather but still offers a balance of quality and cost. What are the common finishes applied to leather? Common finishes include aniline and semi-aniline (which preserve the natural look), pigmented (which provides a uniform color and protective layer), nubuck (sanded for a velvety surface), and suede (made from the inner layers with a napped finish). What is the tanning process in leather production? Tanning is the process of treating animal hides to prevent decay and make them durable. It involves soaking the hides in tannins (from tree bark) or chemicals (like chromium salts), curing, and drying to stabilize and preserve the leather. How does the structure of leather affect its durability? The structure of leather, particularly the density and arrangement of collagen fibers in the dermis, affects its strength and flexibility. Tightly packed and well-organized fibers result in more durable and resilient leather. What are some common uses of leather? Leather is used in fashion (shoes, bags, jackets), furniture (sofas, chairs), automotive interiors, industrial applications (tool grips, gloves), sports equipment (baseball gloves, footballs), and musical instruments (drumheads, accordion bellows). What are sustainable practices in leather production? Sustainable practices in leather production include using eco-friendly tanning methods that reduce chemical and water use, recycling leather scraps into new products, and developing alternative leathers from plant-based materials or lab-grown processes. These practices aim to minimize environmental impact and promote ethical production.Anatomy of leather FAQ