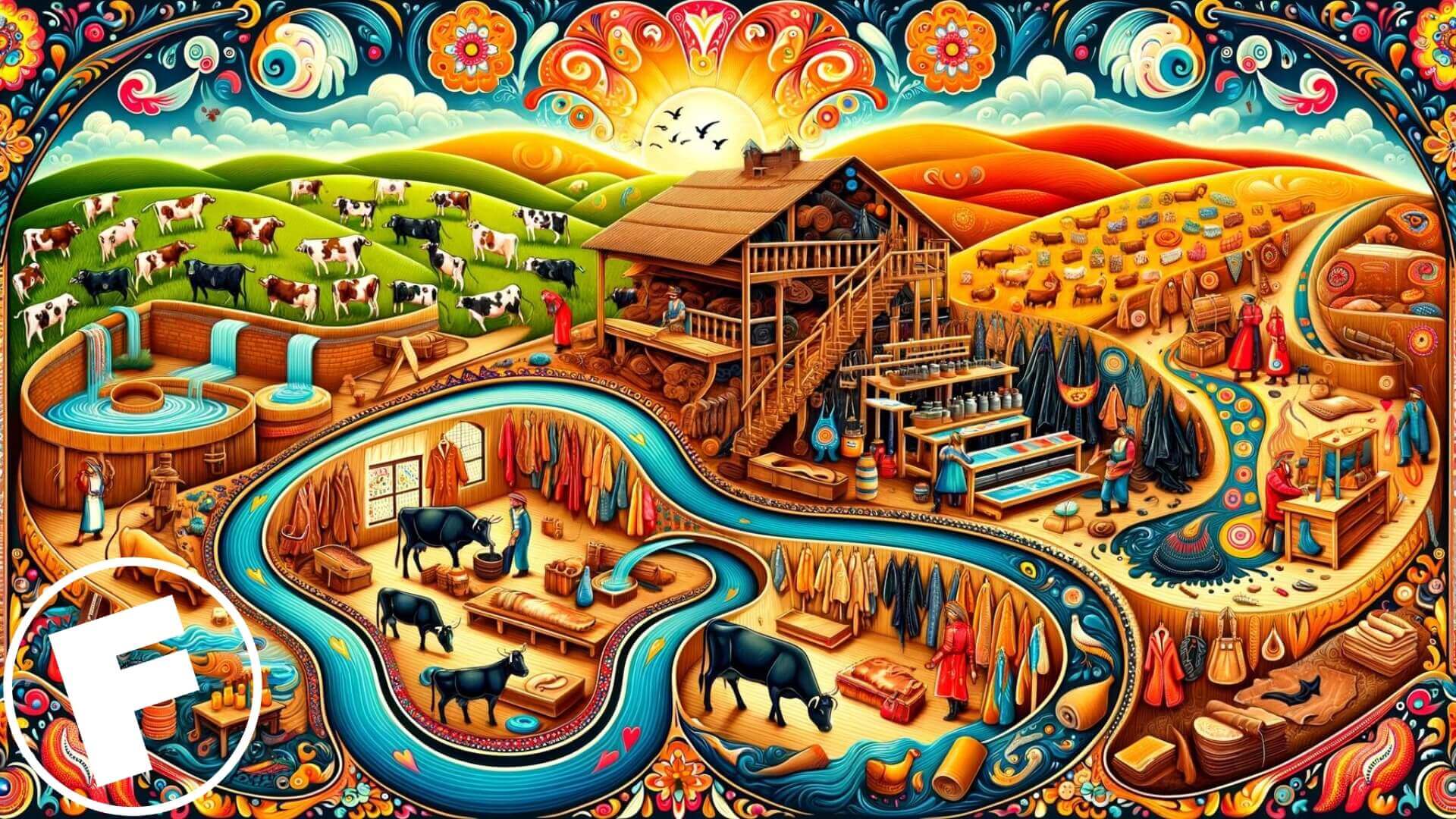

Farm to Product: The Lifecycle of Leather

Leather is one of those materials that never really goes out of style. Whether it’s in the form of a timeless leather jacket, a sturdy pair of boots, or a sleek handbag, leather products are everywhere.

But have you ever stopped to think about how that leather item you love so much came to be? The journey from farm to finished product is fascinating and involves multiple stages, each crucial in creating high-quality leather goods.

Understanding the lifecycle of leather not only gives us a deeper appreciation for the craftsmanship behind these products but also highlights the various environmental and ethical considerations involved in the process.

In this article, we’ll take a closer look at each step, from the farm’s origins to the final touches that prepare a leather product for the market. So, sit back and join us on this insightful journey through the world of leather.

Origins of leather: The farm

The journey of leather begins long before it reaches the tanneries and factories. It starts on farms where livestock are raised primarily for meat, milk, and wool. The hides and skins from these animals, often a byproduct of the meat industry, are the raw materials for leather production.

The role of livestock farming in leather production

Cows, pigs, goats, and sheep are the most common leather sources. Each type of animal hide has unique characteristics that make it suitable for different products.

For instance, cowhide is known for its durability and is commonly used for furniture and car interiors, while goat leather is softer and more flexible, making it ideal for gloves and small accessories.

Ethical considerations and animal welfare are increasingly important in livestock farming. Responsible farms adhere to strict guidelines to ensure the humane treatment of animals. This includes providing adequate space, proper nutrition, and humane slaughtering practices.

Consumers today are more aware and concerned about these issues, which has led to greater transparency and improvements in animal welfare standards.

Environmental impact of livestock farming

Livestock farming, however, does have significant environmental impacts. It requires vast amounts of land and resources, and the farming process contributes to deforestation, especially in regions where forests are cleared to create grazing land.

Additionally, livestock produces methane, a potent greenhouse gas contributing to climate change.

Addressing these environmental issues is crucial for the sustainability of the leather industry. Some farms are adopting more sustainable practices, such as rotational grazing, which can improve soil health and reduce the carbon footprint.

Others are investing in technologies to capture and reduce methane emissions. As consumers, supporting products from these responsible farms can help drive positive change in the industry.

By understanding the origins of leather, we gain a greater appreciation for the raw materials and the initial steps that set the foundation for high-quality leather products.

The farm is just the beginning of a leather product’s lifecycle, leading us next to the transformative process of tanning.

Tanning: The transformation process

Once the raw hides are collected from the farm, they are sent to tanneries for processing. Tanning is critical in transforming perishable raw hides into durable and versatile leather. This process preserves the hides and prepares them for use in various products, ensuring they can withstand the test of time.

Tanning and its purpose

Tanning is the chemical treatment of hides to convert them into leather. The primary goal is to prevent the hides from decomposing, making them stable and suitable for use.

This transformation involves removing the hair and flesh, stabilizing the protein structure, and enhancing the hide’s flexibility, durability, and water resistance.

Types of tanning processes

There are several tanning methods, each with its own characteristics and applications. The most common are vegetable tanning and chrome tanning, but alternative methods are also gaining popularity.

Vegetable Tanning: This traditional method uses natural tannins extracted from plant materials such as tree bark, leaves, and fruits. Vegetable-tanned leather is known for its rich, earthy colors and ability to develop a unique patina over time. It is often used for high-end products like saddlery, belts, and artisanal goods. The process is more time-consuming and labor-intensive but is considered more environmentally friendly.

Chrome Tanning: Developed in the 19th century, chrome tanning uses chromium salts to treat the hides. This faster method produces more flexible and water-resistant leather, making it suitable for various applications, including footwear, garments, and upholstery. However, due to the chemicals involved, chrome tanning can have significant environmental impacts, leading to concerns about water pollution and waste management.

Alternative Methods: To address environmental concerns, some tanneries are exploring alternative tanning methods, such as synthetic tanning and aldehyde tanning. These processes aim to reduce the environmental footprint and improve worker safety while maintaining the quality and durability of the leather.

Environmental and health impacts of tanning

Tanning can have substantial environmental and health impacts, particularly regarding water usage and chemical exposure. Traditional tanneries use large amounts of water and often release untreated wastewater into rivers and streams, leading to pollution and ecosystem damage.

The chemicals used in tanning, especially chrome tanning, can pose serious health risks to workers if proper safety measures are not in place.

Exposure to these chemicals can lead to skin irritation, respiratory problems, and long-term health issues.

To mitigate these impacts, many tanneries are adopting more sustainable practices. This includes recycling water, using eco-friendly chemicals, and implementing rigorous safety protocols to protect workers.

Additionally, some tanneries are investing in advanced wastewater treatment systems to reduce pollution and improve the overall environmental footprint of the tanning process.

The tanning stage is pivotal in the lifecycle of leather, transforming raw hides into a versatile material ready for further processing. Understanding the different tanning methods and their impacts helps us appreciate the complexities of creating high-quality leather products.

Next, we’ll explore the post-tanning processes that further refine and enhance the leather.

Post-tanning processes

After the hides have been tanned, they undergo several additional processes to refine and enhance the leather. These post-tanning steps are crucial in determining the leather’s final quality, texture, and appearance, ensuring it meets the specific requirements for its intended use.

Splitting and shaving the leather

Once the hides are tanned, they are often too thick for most applications. The first step in post-tanning is splitting the leather to the desired thickness. Splitting involves separating the hide into two or more layers.

The top layer, known as top grain, is of the highest quality and retains the hide’s natural grain. The bottom layers can be further processed into suede or bonded leather.

After splitting, the hides are shaved to achieve uniform thickness. This step ensures consistency across the entire hide, making it easier to work with during manufacturing.

Dyeing and finishing

Dyeing is a critical step in giving the leather its color. Different dyeing techniques can be used, depending on the desired outcome. Aniline dyes penetrate the leather, enhancing its natural characteristics and providing a rich, deep color.

On the other hand, pigment dyes sit on the surface of the leather and are often used for more vibrant and consistent colors.

Once dyed, the leather undergoes various finishing treatments to achieve the desired texture and appearance. This can include:

- Embossing: Imprinting patterns or textures onto the surface.

- Glazing: Buffing and polishing the leather to create a glossy finish.

- Oiling and Waxing: Adding oils or waxes to improve suppleness and water resistance.

Quality control

Quality control is an essential aspect of the post-tanning process. Leather is graded based on its quality, with higher grades having fewer imperfections and a more consistent appearance. Inspectors check for defects such as scars, holes, and uneven dyeing.

Only the best quality leather is used for high-end products, while lower grades may be used for items where aesthetic perfection is less critical.

By the end of the post-tanning processes, the leather has been thoroughly refined and is ready to be transformed into finished products. These steps ensure that the leather looks good and performs well in its final application.

Next, we will explore the manufacturing process where leather is crafted into a wide range of products.

Manufacturing leather products

With the leather now expertly tanned and finished, it can be crafted into many products. The manufacturing process involves several meticulous steps that combine traditional craftsmanship with modern technology to produce high-quality leather goods.

Cutting and pattern-making

The first step in manufacturing is cutting the leather into pieces that will form the product. This process begins with creating patterns, which serve as templates for cutting the leather.

Skilled craftsmen or automated machines carefully lay out these patterns on the leather to maximize material use and minimize waste.

Efficient material use is crucial, as leather is a valuable resource. Precision in cutting ensures that every piece of leather is utilized effectively, reducing scrap and contributing to sustainable practices within the industry.

Assembly and stitching

Once the leather pieces are cut, they are assembled and stitched together. This stage is where the product starts to take shape. Various techniques are employed depending on the product type and the desired aesthetic.

For example:

Hand stitching: Often used for high-end, artisanal products where visible stitches add charm to the design.

Machine stitching: Used for mass-produced items, providing consistency and speed.

The craftsmanship involved in stitching is paramount. Experienced artisans ensure that seams are strong and the stitching is even, contributing to the durability and appearance of the final product.

Adding hardware and accessories

The next step involves adding hardware and accessories, which can significantly enhance the functionality and aesthetic of leather products.

This includes attaching zippers, buckles, snaps, and decorative elements. The choice of hardware is critical, as it must complement the leather’s quality and style while being durable enough to withstand regular use.

Hardware is often selected based on the product’s intended use. For instance, robust buckles are essential for belts and bags, while sleek, elegant clasps may be chosen for wallets and small accessories.

Finishing touches

Finally, the product undergoes finishing touches to meet quality standards and design specifications. This can include additional polishing, edge painting, and final inspections. These steps ensure that every detail is perfect before the product reaches the consumer.

The manufacturing process transforms leather from raw material to a functional and aesthetically pleasing product. Each step, from cutting and assembly to finishing touches, requires high skill and attention to detail. Understanding this process gives us a deeper appreciation for the craftsmanship involved in creating leather goods.

Sustainability in the leather industry

As awareness of environmental and ethical issues grows, the leather industry increasingly focuses on sustainability.

This involves adopting eco-friendly practices, reducing waste, and ensuring ethical treatment of animals and workers. Let’s explore some of the innovations and initiatives driving this shift.

Innovations in sustainable leather production

The leather industry has seen significant advancements aimed at reducing its environmental impact. Here are some key innovations:

Eco-Friendly Tanning Methods: Traditional tanning processes, especially chrome tanning, can harm the environment. Many tanneries are adopting vegetable tanning and other eco-friendly methods that use natural and biodegradable materials. These processes reduce chemical waste and produce leather that is safer for workers and consumers.

Water Recycling and Treatment: Tanneries are major consumers of water and sources of wastewater. Innovative water recycling and treatment systems are being implemented to minimize water usage and prevent pollution. These systems treat wastewater to remove harmful chemicals before it is released back into the environment.

Energy Efficiency: Reducing energy consumption is another critical aspect of sustainable leather production. Tanneries are increasingly using renewable energy sources, such as solar and wind power, and improving energy efficiency in their operations.

Recycling and Upcycling Leather Waste: Leather production generates waste through offcuts and scraps. Many companies are now finding creative ways to recycle and upcycle this waste. For example, smaller leather pieces can be used to create accessories or ground-up leather can be used in composite materials.

Brands and Initiatives Leading the Way

Several brands and organizations are at the forefront of promoting sustainability in the leather industry. These pioneers are setting new standards and inspiring others to follow suit. Some notable examples include:

- Fibrenew: We’ve stood behind our sustainability agenda for 35+ years. Pioneers in the leather, vinyl, and plastic restoration game, we’ve been earnestly committed to eco-friendliness, going hand-in-hand with people and profit since day 1.

- ECCO Leather: Known for its innovative approaches, ECCO Leather has developed a process called DriTan™ that reduces water usage in tanning by up to 20 liters per hide.

- Elvis & Kresse: This British brand rescues leather offcuts from luxury manufacturers and upcycles them into stylish accessories, preventing tons of leather from ending up in landfills.

- Leather Working Group (LWG): An industry-led organization, LWG promotes sustainable and responsible practices within the leather industry. They certify tanneries that meet their rigorous environmental standards.

Consumer choices and their impact

Consumers play a vital role in driving sustainability in the leather industry. Consumers can support brands and products that prioritize ethical and sustainable practices by making informed purchasing decisions. Here are some tips for making eco-friendly choices:

Research Brands: Look for transparent brands about their sourcing and production processes. Certifications from organizations like the Leather Working Group can be a good indicator of sustainable practices.

Choose Quality Over Quantity: Investing in high-quality, durable, and timeless leather products can reduce the frequency of purchases and overall waste.

Support Secondhand and Upcycled Products: Buying secondhand leather goods or products made from upcycled leather helps extend the lifecycle of the material and reduce waste.

Sustainability is becoming an integral part of the leather industry’s future. The industry is moving towards a more sustainable and ethical model through innovative practices, responsible brands, and conscious consumer choices.

Challenges and future trends

Despite significant progress towards sustainability, the leather industry faces various challenges. Addressing these issues is crucial for ensuring the industry’s future viability and aligning with environmental and ethical standards.

Let’s explore some of these challenges and the emerging trends that could shape the future of leather production.

Current challenges in the leather industry

Environmental Concerns:

Pollution: Traditional tanning processes can lead to significant water and soil pollution. Many tanneries, especially in developing countries, lack proper waste management systems, leading to harmful chemical runoff.

Resource Use: Leather production requires large amounts of water, land, and energy. The environmental footprint of livestock farming and tanning remains a critical issue.

Ethical Considerations:

Animal Welfare: Ensuring the humane treatment of animals is a major concern. While some farms adhere to high welfare standards, others do not, leading to ethical dilemmas for consumers and producers.

Worker Safety: The tanning process involves exposure to hazardous chemicals, which can pose health risks to workers. Ensuring safe working conditions and proper protective measures is essential.

Economic Pressures:

Cost of Sustainable Practices: Implementing eco-friendly and ethical practices often involves higher costs. Smaller businesses, in particular, may struggle to afford the necessary investments in technology and infrastructure.

Future Trends and Advancements

Biodegradable and Lab-Grown Leather:

Biodegradable Leather: Innovations in producing biodegradable leather from natural sources are gaining traction. These materials decompose more easily, reducing long-term environmental impact.

Lab-Grown Leather: Lab-grown or cultured leather, made from animal cells, offers a promising alternative. This method can significantly reduce the need for livestock farming and its associated environmental issues while still producing high-quality leather.

Technological Innovations in Production:

Advanced Waste Management: New technologies are improving waste management in tanneries, allowing for more efficient recycling and treatment of wastewater.

Automation and AI: Automation and artificial intelligence are being used to enhance precision and efficiency in leather cutting and pattern making, reducing waste and improving productivity.

Circular Economy Models:

Recycling and Upcycling: Embracing circular economy principles, the industry focuses on recycling and upcycling leather waste. This approach minimizes waste and maximizes the lifecycle of leather products.

Product Longevity: Emphasizing durable designs and high-quality materials, brands encourage consumers to invest in long-lasting products rather than disposable fashion.

Consumer Awareness and Demand:

Ethical Consumerism: Increasing awareness about environmental and ethical issues drives demand for sustainable and ethically produced leather goods. Consumers are willing to pay a premium for products that align with their values, a sentiment that is even catching up in regions like China that have historically not prioritized sustainability.

Transparency and Traceability: Brands are enhancing transparency and traceability in their supply chains. Providing detailed information about sourcing, production processes, and certifications helps build consumer trust.

The leather industry is at a pivotal point, facing both significant challenges and exciting opportunities. By embracing innovative technologies, sustainable practices, and ethical standards, the industry can evolve to meet the demands of a more conscious and environmentally aware market.

As we move forward, continued collaboration between producers, brands, and consumers will be essential in driving positive change and ensuring the future of leather production is both sustainable and ethical.

Fibrenew = Leather champions for life

The journey from farm to finished leather product is intricate and fascinating, involving multiple stages of transformation and refinement.

Understanding this lifecycle enhances our appreciation for the craftsmanship involved and highlights the importance of sustainability and ethical practices in the industry.

From the origins of livestock farming to the final touches in manufacturing, every step plays a crucial role in shaping the quality and sustainability of leather products. As consumers become more aware of environmental and ethical issues, the demand for responsibly produced leather continues to grow.

By supporting sustainable practices and making informed choices, we can all contribute to a more sustainable future for the leather industry.

Get in touch with your local Fibrenew professional for all your leather, plastic, and vinyl repair needs.

Want to run a business that gives you incredible earning potential and the flexibility to take control of your time and life? Join the Fibrenew Family!

Check out our free Franchise Information Report for everything you need to know.

Also, enjoy these valuable resources on all things leather, plastic, and vinyl repair, franchising, sustainability, and more:

What is the life cycle assessment (LCA) of leather? Life cycle assessment (LCA) is a methodology for evaluating the environmental impacts of leather production from raw material extraction to disposal. It considers factors such as resource use, emissions, and waste generation throughout the leather’s lifecycle. What are the main stages involved in leather manufacturing? Leather manufacturing involves several stages: sourcing raw hides, leather tanning, post-tanning processes, and final product manufacturing. Each stage contributes to the overall quality and environmental footprint of the leather. How does leather processing impact the environment? Leather processing can significantly impact the environment through resource consumption (water, energy), emissions (greenhouse gases, pollutants), and solid waste generation. Sustainable practices are essential to mitigate these effects. What are the environmental concerns associated with leather shoes? Leather shoes contribute to environmental impacts such as water and energy consumption, chemical use in tanning, and waste generation. Life cycle assessment (LCA) helps understand and reduce these impacts. What is leather tanning, and why is it important? Leather tanning is the process of treating raw hides with tanning agents to stabilize the collagen and make the leather durable and resistant to decomposition. It’s a crucial step in converting hides into usable leather. What methodologies are used in leather life cycle analysis? Leather life cycle analysis methods include assessing resource use, emissions, and impacts on human health and ecosystems. Tools like LCA provide a comprehensive view of leather products’ environmental footprint. How is solid waste managed in leather production? Solid waste from leather production, such as trimmings and sludge, is managed through recycling, upcycling, and proper disposal. Some innovative approaches involve converting waste into useful by-products. What are tanning agents, and how do they affect the environment? Tanning agents, such as chromium salts and vegetable tannins, are chemicals used in the tanning process. They can have varying environmental impacts, with some posing toxicity risks and contributing to pollution if not managed properly. What are the toxicity concerns in leather processing? Toxicity concerns in leather processing include exposure to hazardous chemicals like chromium, which can affect both human health and the environment. Proper safety measures and alternative tanning methods are essential to address these issues. How does leather production in countries like India and Bangladesh affect the environment? Leather production in India and Bangladesh often faces challenges such as pollution, inadequate waste management, and worker safety issues. Efforts are ongoing to improve sustainability and reduce the environmental footprint in these regions. What are the human health risks associated with leather tanning? Human health risks in leather tanning include exposure to toxic chemicals, respiratory problems, and skin conditions. Ensuring proper protective equipment and safe working conditions is critical for worker health. What impact categories are considered in leather life cycle assessment? Impact categories in leather life cycle assessment include resource depletion, greenhouse gas emissions, water pollution, and human toxicity. These categories help identify and address the most significant environmental impacts. What is liming in the context of leather processing? Liming is a process in leather preparation where hides are soaked in an alkaline solution to remove hair and other unwanted components. This step is essential for preparing the hides for tanning. How can leather products be reused or recycled? Leather products can be reused or recycled by repairing, repurposing, or upcycling into new products. Recycling helps extend the lifecycle of leather and reduces waste. What are the different types of tanning systems? Tanning systems include vegetable, chrome, synthetic, and aldehyde tanning. Each system has its advantages and environmental implications. What is bovine leather, and how is it different from other types of leather? Bovine leather comes from cow hides and is known for its durability and versatility. It is the most commonly used type of leather, compared to other types like goat or sheep leather, which have different properties. How is collagen important in leather production? Collagen is the main structural protein in animal hides. During tanning, collagen fibers are stabilized to create durable and flexible leather. What are the resource depletion concerns in leather manufacturing? Resource depletion concerns in leather manufacturing include the high water and energy requirements and the use of land for livestock farming. Sustainable practices aim to reduce these impacts. How does life cycle analysis help improve the sustainability of leather production? Life cycle analysis helps identify the environmental impacts of each stage of leather production, allowing manufacturers to implement more sustainable practices and reduce their overall footprint.The lifecycle of leather FAQ